For a famous Italian company in the pneumatic field we have realized 100.000 neodymium rings for pneumatic cylinder magnetic sensor.

The final customer’s need was to improve sensor’s reading precision reducing dimensions.

His first solution was a plasto-ferrite ring, axially magnetized. The low properties of this magnetic material forced the use of a lumbering magnet, beyond the necessity of keeping the ring very close to the sensor for a better reading.

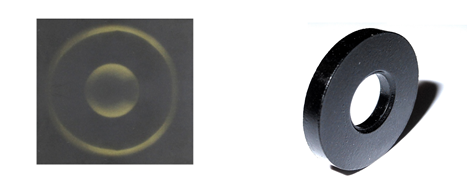

Our work, instead, focused on the realization of sintered neodymium magnet ring, axially magnetized and coated with epoxy resin.

The ring magnetic performances, definitely higher than previous solution, allowed to reduce sensor’s dimension, offering a more precise reading. Consequently, the distance between magnet and sensor increased. The axial magnetization of neodymium ring has been realized more perpendicular comparing with the one of plasto-ferrite magnet. In the end, epoxy coating has garanted a longer life of pneumatic cylinder.

End customer has finally obtained a better sensor’s precision, putting on the market an evolved system, with reduced sizes.

Compo Tech Co. is able to projects and produce customized magnets, to satisfy every customer needs.